Originally widely used in the automotive industry, robots have now begun to extend to the electronics industry, home appliances, furniture industry and other industries, industrial robots are increasingly appearing in China's manufacturing factories.

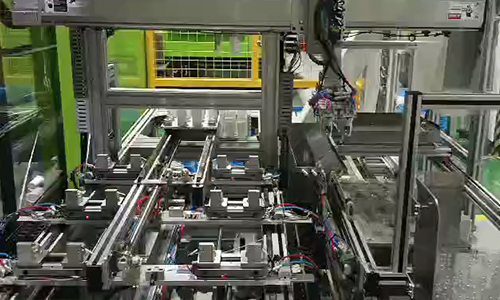

This is the scene in the Zhuhai Gree air conditioning injection moulding plant. The director of the plant said, where machines and people have been completely separated, the previous need for people to operate the machine, now can be completed alone a series of process operations, and people are only responsible for the final packing.

Through this automation improvement, our current personnel, has been from the initial more than 300 people, reduced to now only 100 people, so the effect of staff reduction is still relatively obvious. We have also improved efficiency by 20 per cent.

China's manufacturing sector is undergoing a slow but profound change - the massive use of industrial robots. Germany-based International Federation of Robotics data released last month showed that a total of 3.7 million industrial robots were sold on the Chinese market in 2013, nearly three times as many as in 2012. China has not only become the world's largest robot market, but also the fastest growing market.

In Guangzhou in the Pearl River Delta region, the government has proposed that by 2020, more than 80 per cent of the city's manufacturing enterprises to apply industrial robots and intelligent equipment. In the ‘factory of the world’ known as Dongguan, a sample survey organised by the government showed that in the past five years, a total of 66% of the city's enterprises have invested in capital to carry out the ‘machine for man’ work, 92% of the enterprises said that in the next two years will continue to increase the investment or ready to carry out Related work.

In recent years, China's labour market is changing, the phenomenon that factories in developed coastal manufacturing areas are unable to recruit workers is widespread. On the other hand, China's manufacturing costs have been rising. Influenced by these factors, many enterprises will ‘machine for man’ as a way out to reduce production costs.

so I rightly want to improve my per capita benefit, it is not called an employee day and night to bury their heads in the sand, 24 hours a day to work with this amount of balance of the per capita benefit, I think the standard is too low. So this is what we need to change, not that for a simple change in the cost of labour to do automation, you are based on the scale of your business development and the positioning of your kind of business need to make such changes.

Release time:2023-05-29

Release time:2023-05-29

Reading:728

Reading:728

Back to list

Back to list