The China International Industry Fair (hereinafter referred to as ‘Industry Fair’) is being held has once again become the main arena for the robotics industry to compete with the leading companies, such as ABB, Kuka, Fanuc and other companies have brought new products to debut, so that the audience has a close experience of the future of intelligent manufacturing.

Among them, ABB showed two new robots, respectively IRB 910INV inverted SCARA robot and IRB 1100 robot, intended for the future of the factory to create the latest flexible, intelligent, customised solutions.

According to reports, the IRB 1100 robot is ABB's most compact and lightweight robot to date, reducing beat time by 35 per cent to improve productivity and delivering leading repeat positioning accuracy. With a 10 per cent smaller footprint and 20 per cent less weight than previous generations of robots, the IRB 1100 has a slimmer, lighter body that allows it to be flexibly deployed in confined spaces and on existing automated production lines.

KUKA presented the robot KMR CYBERTECH nano for the first time in the world, a prototype that is the second mobile robot cell from KUKA after the KMR iiwa, which is not only self-contained, but also highly flexible to meet the requirements of Industry 4.0. The prototype is the second mobile unit from KUKA after the KMR iiwa. The KMR CYBERTECH nano is expected to be available in the third quarter of 2019, with an initial version boasting a 10kg load capacity, according to the report.

In addition to showcasing robots, industry giants have also moved smart factories into the IFE site.

Among them, ABB demonstrated a series of industry-specific solutions, including electric vehicle battery assembly applications, as well as a new conveyor belt tracking solution that significantly improves the speed of picking, packing and palletising applications.

Fanuc showed nearly 20 sets of industry automation solutions on the scene, so that the audience can experience close to the automotive vehicle, new energy, logistics, welding, IT electronics and other industries of intelligent manufacturing. Among them, the two-colour cup injection packaging information system is particularly eye-catching. Production execution system (MES) is the focus of the intelligent factory planning. The system takes the two-colour cup as the display product, and through Fanuc's production execution system, it carries out information management on the whole production process of the product. From WeChat remote ordering, injection moulding machine injection production, robot assembly and packaging to the final product storage and management, through the AGV and collaborative robots cooperate with the product to carry out the transfer of each station, demonstrating the model of unmanned intelligent factory.

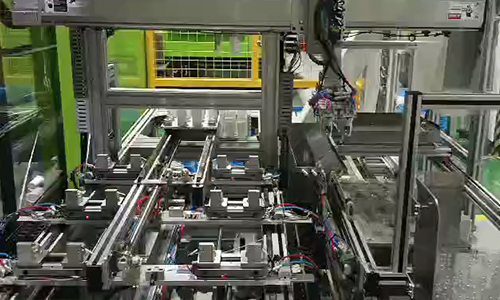

In addition, Delta, as an active promoter of intelligent manufacturing, also demonstrated a complete intelligent factory overall solution containing intelligent production, intelligent office and plant energy management and other elements at this year's Industrial Fair. Among them, in the display area presenting intelligent production, with the Delta Manufacturing Execution System (DIAMES) as the core, integrating a variety of Delta's industrial automation software and hardware products, the intelligent production line that can place orders in real time, produce automatically and monitor the progress of the operation and equipment operation data, make gifts for the audience to experience the ‘future of intelligent manufacturing! The future of smart manufacturing’.

According to reports, Delta programmable logic controller (PLC) intelligent demonstration production line, for example, the introduction of intelligent manufacturing can be achieved to increase production capacity by 40%, 62% reduction in the production area, 88% reduction in direct manpower requirements.

Release time:2023-05-29

Release time:2023-05-29

Reading:898

Reading:898

Back to list

Back to list